Jit Meaning: Unpacking Slang & Lean Business Strategy

The term "jit" is a fascinating linguistic chameleon, seamlessly navigating two vastly different realms: the dynamic landscape of urban youth slang and the rigorous world of supply chain management. Depending on the context, the jit meaning can shift from referring to a young, sometimes inexperienced individual to describing a highly optimized inventory control system. This duality makes "jit" a word worth exploring, not just for its colloquial charm but also for its profound impact on global manufacturing and efficiency.

In this comprehensive guide, we'll embark on a journey to unravel the multifaceted jit meaning. We'll delve into its origins and usage in everyday conversation, particularly within Generation Z's lexicon, before transitioning to its pivotal role as an acronym for "Just-In-Time" inventory management. Whether you're trying to understand your teenager's lingo or seeking insights into cutting-edge business strategies, this article aims to provide clarity and depth, ensuring you grasp every nuance of this intriguing term.

Table of Contents

- The Dual Nature of "Jit": Slang vs. Strategy

- "Jit" as Urban Slang: A Generational Lexicon

- Beyond Slang: Understanding Just-In-Time (JIT) Inventory

- The Core Principles of JIT: Lean Management in Action

- Benefits of Implementing JIT Inventory Systems

- The Challenges and Risks of JIT Adoption

- Is JIT Right for Your Business? Assessing Readiness

- JIT in a Volatile World: Adapting to Disruption

- The Future of JIT: Evolution in Supply Chains

The Dual Nature of "Jit": Slang vs. Strategy

The term "jit" truly embodies the versatility of language. On one hand, it's a casual, often affectionate or mildly critical, descriptor used by younger generations. On the other, it represents a sophisticated and globally adopted business methodology. This stark contrast highlights how a single phonetic string can carry such diverse meanings depending on the domain. Understanding the specific jit meaning you encounter requires careful attention to context – is it being used in a casual conversation among friends, or in a discussion about manufacturing processes? This article aims to clarify both interpretations, ensuring you're well-versed in the multifaceted nature of "jit.""Jit" as Urban Slang: A Generational Lexicon

In the realm of urban slang and colloquial speech, particularly among Generation Z, the jit meaning refers to a young person, typically a teenager, or someone who is perceived as inexperienced or naive due to their age. This term is commonly used by someone older than the person being referred to. It's often applied to individuals usually between the ages of 12 and 15, who might think they are more mature or "cooler" than they actually are. While it can sometimes be used in a playful or teasing manner, as in "Oh, that jit just being a jit," it frequently carries a slightly disapproving connotation. For instance, the phrase "jit trippin'" implies that the younger person is acting out, being foolish, or causing trouble. The usage of "jit" has become prevalent across various digital communication platforms, including texting, chat applications, TikTok, and Snapchat. Its widespread adoption reflects the dynamic nature of youth language, constantly evolving and adapting to new forms of interaction. Learning how to use it and what it means often comes from observing its application in real-time conversations or trending content. The term captures a specific generational sentiment, distinguishing between older, more experienced individuals and those still navigating the complexities of adolescence and early youth.The Nuances of Slang "Jit": Context and Usage

The specific jit meaning in slang can vary subtly based on context and the speaker's intent. While it generally denotes someone younger or inexperienced, the tone can range from affectionate to mildly exasperated. For example, a friend might say, "I've known Chris since he was a jit," implying a long-standing relationship with someone who was once much younger. This usage highlights the passage of time and the growth of the individual. However, if someone exclaims, "That jit really messed up the plan," it clearly conveys frustration or disapproval of the younger person's actions or lack of understanding. The term's popularity has soared with the rise of platforms like TikTok, where short-form videos often feature interactions between different age groups. This exposure has cemented "jit" as a recognizable piece of modern youth vernacular. It's not uncommon to hear it in urban music or see it in social media captions, further solidifying its place in contemporary language. Understanding these nuances is crucial to correctly interpreting the intent behind its use, whether it's a lighthearted jab or a genuine expression of annoyance.Beyond Slang: Understanding Just-In-Time (JIT) Inventory

Shifting gears entirely, the acronym JIT stands for "Just-In-Time," a revolutionary inventory management and production strategy that has transformed global manufacturing. Unlike the informal jit meaning, JIT in business refers to a lean management process where firms manufacture goods or order raw materials only when demand arises, or just before they are needed for production. This approach stands in stark contrast to traditional inventory models that involve stockpiling large quantities of products and raw materials. The core philosophy behind JIT is to minimize inventory holding costs and waste by ensuring that components arrive at the production line precisely when they are required, and finished goods are produced only when there's a customer order. This method helps maintain a lean inventory, significantly enhances cash flow by reducing capital tied up in stock, and drastically reduces waste from obsolescence, damage, or overproduction. By focusing on keeping as little inventory on hand as possible, businesses can operate with greater agility and responsiveness to market demands. The success of JIT relies heavily on meticulous planning, seamless coordination with suppliers, and a deep understanding of production flows. It's a testament to how strategic thinking can lead to profound operational efficiencies.The Origins of JIT: Toyota's Lean Revolution

The concept of JIT inventory management originated in Japan, famously adopted by Toyota in the 1970s as a cornerstone of its Toyota Production System (TPS). Faced with limited space and resources, Toyota sought a way to produce vehicles efficiently without the vast warehouses full of parts common in Western manufacturing. Taiichi Ohno, a key figure at Toyota, is often credited with developing and refining the JIT system, drawing inspiration from various sources, including American supermarkets where shelves are restocked only as items are purchased. JIT is intrinsically linked to Kaizen, a Japanese term meaning "change for the better" or continuous improvement. In the JIT framework, all parts of any production or service system, particularly people, are interconnected and mutually dependent on generating successful outcomes. This interconnectedness means that any inefficiency or defect in one part of the system immediately impacts the whole, driving a continuous effort to identify and eliminate waste. Toyota's pioneering adoption of JIT demonstrated its immense potential, setting a new global standard for operational excellence and influencing countless industries worldwide. The success of TPS, with JIT at its heart, underscored the profound impact of lean principles on productivity and quality.How JIT Inventory Management Works

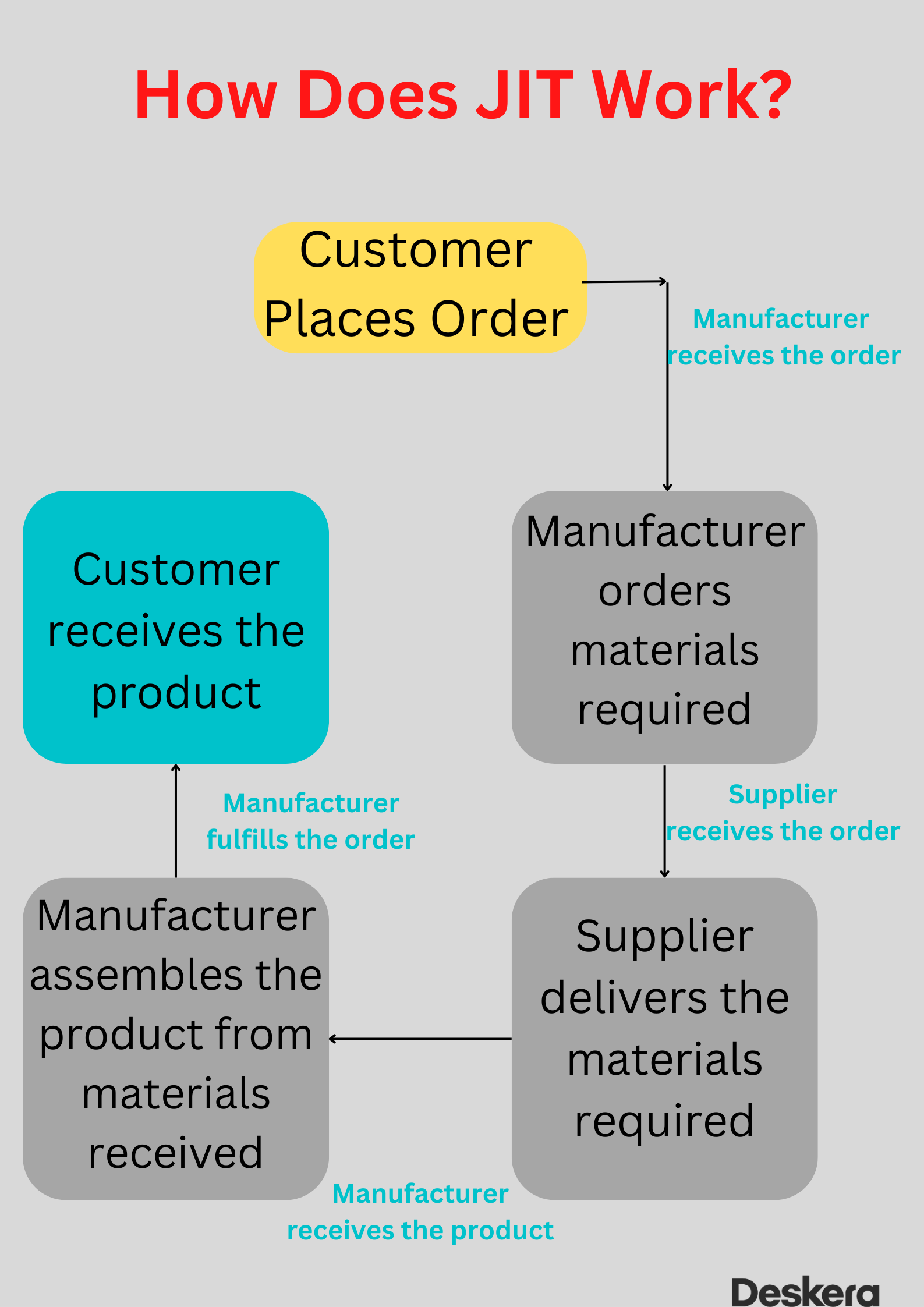

At its core, JIT inventory management operates on a pull system, where production is triggered by actual customer demand rather than forecasted demand. Instead of pushing products through the manufacturing process, items are "pulled" through as needed. This means raw materials are ordered in small, frequent shipments, arriving just in time for production. Finished goods are then produced only when a customer places an order, ensuring that inventory levels remain minimal. For example, if a car manufacturer uses JIT, they would receive specific components like seats or engines only a few hours before they are needed on the assembly line, rather than storing them for weeks. This strategy significantly reduces inventory costs, as less capital is tied up in raw materials and finished goods. It also minimizes storage space requirements and reduces the risk of obsolescence or damage to stock. The emphasis is on maintaining a lean inventory, which not only enhances cash flow but also makes it easier to sell the highest quality products that are free of defects and meet (or even exceed) customer expectations, as less time is spent in storage where defects might go unnoticed. The success of JIT relies on highly reliable suppliers, efficient logistics, and a culture of continuous improvement within the organization.The Core Principles of JIT: Lean Management in Action

The jit meaning as a business strategy is synonymous with lean management, focusing on maximizing value while minimizing waste. Several core principles underpin its effectiveness: 1. **Elimination of Waste (Muda):** This is central to JIT. Waste includes overproduction, waiting time, unnecessary transport, over-processing, excess inventory, unnecessary movement, and defects. By producing only what is needed, when it is needed, JIT systematically attacks these forms of waste. 2. **Continuous Improvement (Kaizen):** As mentioned, JIT is deeply intertwined with Kaizen. It fosters a culture where every employee is encouraged to identify and implement small, incremental improvements to processes, aiming for perfection and efficiency. 3. **Pull System:** Production is initiated by customer demand. This contrasts with a push system, where products are made based on forecasts and then "pushed" to the market. A pull system ensures that resources are only used when there is a confirmed need, reducing overproduction. 4. **Quality at the Source (Jidoka):** JIT emphasizes building quality into every step of the production process, rather than relying on inspection at the end. This means empowering workers to stop the production line if a defect is found, preventing the propagation of errors and ensuring that products are free of defects from the outset. 5. **Standardized Work:** Processes are clearly defined and consistently executed, leading to predictability, efficiency, and easier identification of deviations. 6. **Flexible Workforce:** Employees are cross-trained and capable of performing multiple tasks, allowing for quick adaptation to changes in demand or production requirements. These principles collectively enable organizations to operate with unparalleled efficiency, responsiveness, and quality, making JIT a powerful tool for competitive advantage.Benefits of Implementing JIT Inventory Systems

The adoption of JIT inventory management brings a multitude of benefits that can significantly impact a company's bottom line and operational efficiency. Understanding these advantages highlights why the business jit meaning is so highly valued in the corporate world. 1. **Reduced Inventory Costs:** This is arguably the most significant benefit. By keeping minimal stock, companies drastically cut down on storage costs, insurance, security, and the capital tied up in inventory. This lean approach frees up valuable cash flow that can be reinvested elsewhere in the business. 2. **Minimized Waste:** JIT directly addresses various forms of waste, including overproduction, obsolescence, and damage. Since materials are ordered only when needed, there's less risk of products expiring, becoming outdated, or being damaged in storage. This leads to higher quality products and less scrap. 3. **Improved Product Quality:** With smaller batches and a focus on continuous improvement, defects are identified and addressed much faster. This allows companies to sell the highest quality products that are free of defects and meet (or even exceed) customer expectations, enhancing customer satisfaction and brand reputation. 4. **Enhanced Efficiency and Productivity:** The streamlined processes inherent in JIT lead to smoother production flows and reduced lead times. This efficiency translates into higher productivity and the ability to respond more quickly to market changes. 5. **Better Cash Flow:** By reducing the amount of capital tied up in inventory, businesses experience improved cash flow. This financial agility allows for greater investment in research and development, marketing, or other growth initiatives. 6. **Stronger Supplier Relationships:** JIT necessitates close collaboration and trust with suppliers. This often leads to long-term, mutually beneficial partnerships, where suppliers become integral to the production process, ensuring timely and quality deliveries. 7. **Increased Flexibility:** While seemingly counterintuitive, a lean JIT system can be more flexible in adapting to changes in product design or demand, as there's less existing stock to clear before new changes can be implemented. These benefits underscore JIT's role as a strategic imperative for businesses aiming for operational excellence and sustainable growth.The Challenges and Risks of JIT Adoption

While the benefits of JIT are compelling, its implementation is not without significant challenges and risks. The very nature of a lean system means that any hiccup can have amplified consequences. Understanding these potential pitfalls is crucial for any organization considering the JIT approach. 1. **Vulnerability to Supply Chain Disruptions:** Unlike traditional inventory models that allow for excess stock as a buffer, JIT doesn't. This means any disruption in material delivery—be it from natural disasters, geopolitical events, supplier issues, or transportation delays—can lead to costly downtime, halted production, and missed deadlines. When disruption happens, there's nowhere to hide. 2. **Market Unpredictability:** JIT works best in environments with stable and predictable demand. Industries that experience sudden spikes or significant fluctuations in demand may struggle to keep up with the precise timing required by JIT, leading to stockouts or inability to meet sudden surges. 3. **Reliance on Supplier Reliability:** The success of JIT is heavily dependent on the unwavering reliability and punctuality of suppliers. A single unreliable supplier can jeopardize the entire production chain. This necessitates robust supplier relationships, clear communication, and often, multiple supplier options. 4. **Higher Transportation Costs (Potentially):** While JIT reduces inventory holding costs, it often involves more frequent, smaller shipments. This can potentially lead to higher transportation costs compared to fewer, larger bulk deliveries, especially if not managed efficiently. 5. **Lack of Buffer for Quality Issues:** If a batch of raw materials arrives with defects, a JIT system has little to no buffer stock to fall back on. This can immediately halt production until replacement materials arrive, emphasizing the need for stringent quality control at the supplier level. 6. **Complex Implementation:** Transitioning to JIT requires a complete overhaul of existing processes, extensive training for staff, and significant investment in information systems. It's a major undertaking that demands strong leadership and organizational commitment. 7. **Increased Pressure on Employees:** The tight scheduling and interconnectedness of JIT can place increased pressure on employees to perform perfectly and on time, as any delay can impact subsequent stages. Before getting into JIT, companies need to honestly assess whether they're ready for this major strategic shift, weighing the substantial benefits against these inherent risks.Is JIT Right for Your Business? Assessing Readiness

Deciding whether to implement a JIT system is a strategic decision that requires a thorough self-assessment. Given the inherent risks and the profound changes it entails, not every business environment or organizational culture is suitable for JIT. Understanding the nuances of the business jit meaning in this context means evaluating your company's preparedness across several key areas. 1. **Demand Stability:** Does your business operate in an industry with relatively stable and predictable demand? JIT thrives where demand fluctuations are minimal, allowing for precise forecasting and scheduling of material deliveries. Highly volatile markets may find JIT too rigid. 2. **Supplier Relationships:** Do you have a network of highly reliable, responsive, and geographically close suppliers? JIT demands impeccable supplier performance, including on-time delivery and consistent quality. Weak supplier relationships or a lack of alternative suppliers can be a fatal flaw. 3. **Process Control and Quality:** Is your internal production process highly controlled, efficient, and do you have robust quality management systems in place? JIT leaves little room for error; defects must be caught early, ideally at the source, to prevent production halts. 4. **Information Systems:** Do you have advanced information systems capable of real-time inventory tracking, demand forecasting, and seamless communication with suppliers? The precise coordination required by JIT relies heavily on accurate and timely data. 5. **Organizational Culture:** Is your company culture one that embraces continuous improvement (Kaizen), employee empowerment, and cross-functional collaboration? JIT requires a collective mindset where everyone is invested in identifying and solving problems. 6. **Logistics and Transportation:** Are your logistics channels efficient and reliable? Frequent, small deliveries are central to JIT, meaning transportation infrastructure must be robust and cost-effective. 7. **Financial Stability:** While JIT improves cash flow in the long run, the initial transition can be costly, requiring investment in new systems and training. A company needs to be financially stable enough to absorb potential initial disruptions. A candid assessment of these factors will determine if your business is truly ready to embrace the lean principles and the potential transformative power of JIT.JIT in a Volatile World: Adapting to Disruption

The past few years have underscored the fragility of global supply chains, prompting many to question the long-term viability of JIT in an increasingly volatile world. Events like the COVID-19 pandemic, geopolitical tensions, and climate-related disruptions have highlighted the critical challenge of "nowhere to hide" when operating with minimal buffers. However, dismissing JIT entirely would be an oversimplification of its evolving role. The business jit meaning is not static; it's adapting. Instead of abandoning JIT, many companies are exploring hybrid models that incorporate elements of resilience. This might involve: * **Strategic Stockpiling of Critical Components:** For highly vulnerable or long-lead-time components, businesses might maintain a small safety stock, deviating slightly from pure JIT principles. * **Diversifying Supplier Networks:** Reducing reliance on a single supplier or geographical region mitigates risk. This involves cultivating relationships with multiple suppliers, even if it means slightly higher costs. * **Nearshoring/Reshoring:** Bringing production or sourcing closer to home reduces transit times and exposure to international disruptions. * **Enhanced Visibility and Data Analytics:** Investing in advanced supply chain analytics allows companies to foresee potential disruptions and react proactively, rather than reactively. * **Increased Agility and Flexibility:** Building more flexibility into production lines and workforce training enables quicker pivots in response to unexpected changes in demand or supply. The essence of JIT – minimizing waste and maximizing efficiency – remains invaluable. The challenge lies in balancing this efficiency with necessary resilience. The future of JIT likely involves a more nuanced application, where businesses strategically identify and manage risks while still striving for lean operations.The Future of JIT: Evolution in Supply Chains

The evolution of the business jit meaning within supply chain management is far from over. As technology advances and global complexities grow, JIT principles are being re-evaluated and integrated with new paradigms. The future of JIT is likely to be characterized by greater intelligence, adaptability, and integration. 1. **Digital Transformation:** The widespread adoption of IoT (Internet of Things), AI, and blockchain will revolutionize JIT. Real-time data from sensors on production lines and in transit will provide unprecedented visibility, enabling even more precise timing and predictive maintenance. Blockchain can enhance transparency and traceability across the supply chain, building greater trust and efficiency. 2. **Predictive Analytics:** Advanced analytics will move beyond historical data to predict demand fluctuations, potential supply chain disruptions, and even equipment failures with higher accuracy. This will allow JIT systems to be more proactive, anticipating needs rather than just reacting to them. 3. **Hyper-Personalization and Customization:** As consumer demand shifts towards personalized products, JIT will be crucial for managing the complexity of diverse components and smaller batch sizes without accumulating vast inventories of specialized parts. 4. **Sustainable Supply Chains:** JIT's inherent focus on waste reduction aligns perfectly with sustainability goals. Future iterations will likely emphasize not just operational efficiency but also environmental impact, optimizing routes, reducing energy consumption, and minimizing material waste throughout the entire product lifecycle. 5. **Resilient JIT:** The lessons from recent global disruptions will lead to a more "resilient JIT" model. This won't mean abandoning lean principles but rather incorporating strategic buffers, diversified sourcing, and agile manufacturing capabilities to absorb shocks without compromising core efficiencies. The fundamental jit meaning – producing what's needed, when it's needed – will remain a powerful objective. However, its application will become more sophisticated, leveraging technology and strategic foresight to navigate the complexities of modern global commerce.Conclusion

From the casual banter of Gen Z to the intricate mechanics of global manufacturing, the "jit meaning" truly showcases the dynamic nature of language and innovation. We've explored how "jit" can refer to a young, often inexperienced individual in urban slang, used in playful or sometimes disapproving contexts across digital platforms like TikTok and Snapchat. Simultaneously, we've delved deep into JIT (Just-In-Time) as a revolutionary lean management strategy, pioneered by Toyota, that focuses on minimizing inventory, reducing waste, and enhancing efficiency by producing goods only when demand arises. Understanding both facets of this versatile term enriches our grasp of contemporary communication and sophisticated business practices. While the slang "jit" adds flavor to everyday conversation, the business JIT continues to shape industries, pushing the boundaries of operational excellence despite its inherent challenges. As the world evolves, so too will the applications and interpretations of "jit," making it a term worth keeping an eye on. What are your thoughts on the dual nature of "jit"? Have you encountered either meaning in a surprising context? Share your experiences and insights in the comments below! If you found this exploration valuable, please consider sharing this article with others who might be curious about the fascinating world of language and business strategy.

What is Just-in-time (JIT) Inventory?

:max_bytes(150000):strip_icc()/terms_j_jit_FINAL_-48745eb8661844c4becbbaafbf322320.jpg)

Just-in-Time (JIT): Definition, Example, Pros, and Cons

PPT - Just-in-Time and Lean Operations PowerPoint Presentation - ID:470182