Unlocking CNC Meaning: Your Guide To Computer Numerical Control

In the ever-evolving landscape of modern manufacturing, a term frequently surfaces that underpins much of our industrial progress: CNC. But what exactly is CNC meaning, and why is it so pivotal to how products are made today? This technology has revolutionized the way machine tools operate, bringing unprecedented levels of precision, speed, and automation to the production floor.

From the smallest intricate components in medical devices to large, robust parts for aerospace, Computer Numerical Control (CNC) is the silent workhorse behind countless innovations. Understanding its core principles, evolution, and widespread applications is key to appreciating the sophistication of contemporary manufacturing. This comprehensive guide will delve deep into the world of CNC, demystifying its operations and highlighting its profound impact.

Table of Contents

- What is CNC Meaning? Unpacking the Acronym

- The Evolution of CNC: From NC to Smart Factories

- How CNC Machining Works: The Core Process

- Types of CNC Machines and Their Applications

- Materials Processed by CNC Machining

- The Critical Role of CNC in Key Industries

- Accuracy vs. Precision in CNC Machining: Why It Matters

- Advantages and Alternatives to CNC Machining

What is CNC Meaning? Unpacking the Acronym

At its core, **CNC stands for Computer Numerical Control**. It refers to a sophisticated method of automating machine tools using computer programs. Imagine a craftsman meticulously shaping a piece of material, but instead of human hands, a computer program dictates every movement with unfathomable precision. That's the essence of CNC. It's the automated control of machine tools by a computer, a direct input of data from a computer program guiding the device.

- Www Hdhub4ucom

- %E7%A5%9E%E6%9C%A8%E9%BA%97

- Xxxxxx Is Equal To 2024 Download

- Securely Connect Remote Iot Vpc Raspberry Pi Download Windows

- Kid And His Mom Cctv Video Original Free

This technology is not just about cutting or shaping; it's about transforming raw materials into custom parts that would often be impossible to create manually. Whether it's a mill, a lathe, or a router, these machines are guided by computer instructions that control the precision of the instruments. The term "CNC machining" or "CNC manufacturing" encompasses this entire process, signifying a paradigm shift in how products are designed and brought to life. Understanding this foundational **CNC meaning** is the first step to appreciating its revolutionary impact.

The Evolution of CNC: From NC to Smart Factories

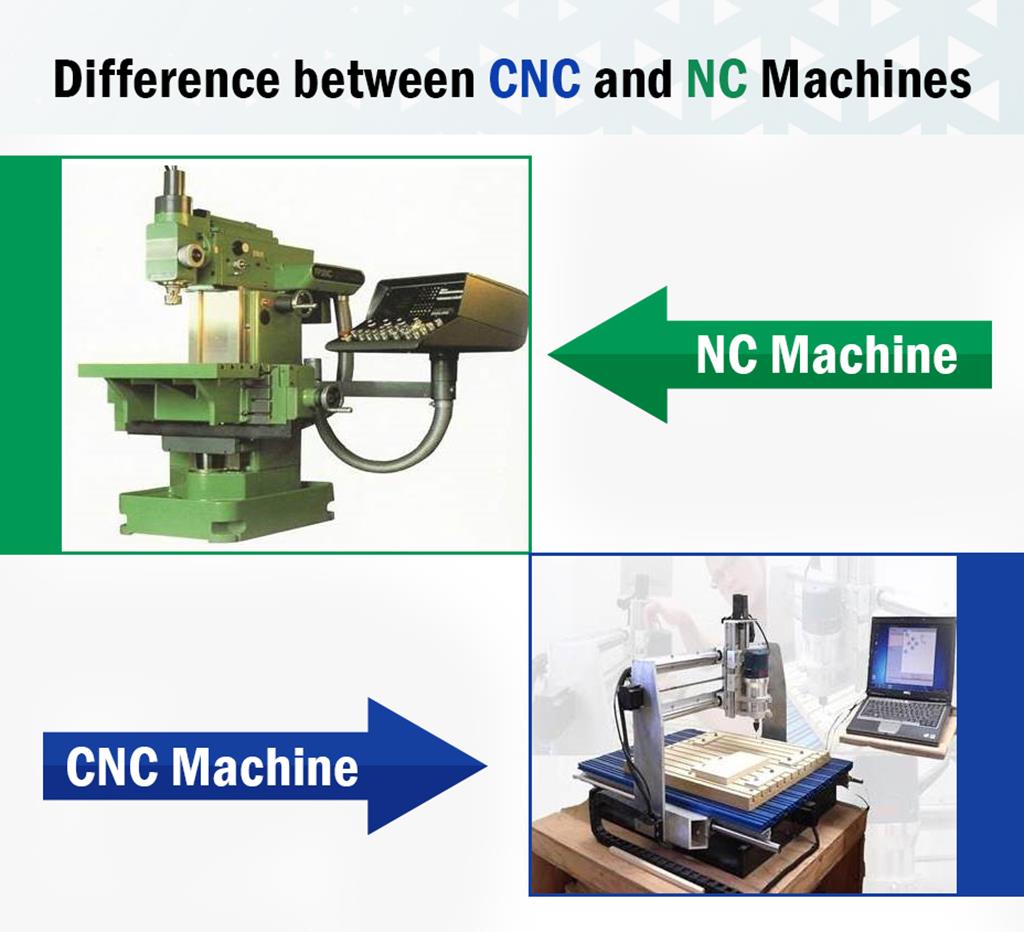

To truly grasp the significance of **CNC meaning**, it's helpful to look back at its origins. Computer Numerical Control is an evolution of Numerical Control (NC). In the NC era, machine tools were directly managed by data storage media such as punched cards or punched tape. Think of it as a rudimentary form of automation, where instructions were fed into the machine in a very literal, physical format. This early form, while innovative for its time, was limited in its flexibility and required significant manual intervention for changes.

The advent of computers changed everything. By integrating computer processing power, CNC introduced a level of flexibility, programmability, and error correction that NC simply couldn't offer. This transition from physical media to digital code was revolutionary. It allowed for complex designs, quick modifications, and the ability to store and reuse programs easily. Today, CNC technology has continued to evolve, playing an essential role in the operation of industrial robots and paving the way for "smart factories" where machines communicate and optimize processes autonomously. This continuous advancement underscores how CNC impacts manufacturing industries globally, moving from simple automation to highly integrated, intelligent production systems.

- Yellow Dress Girl Rock Paper Scissors

- Xxx Is Equal To 2025

- Wasmo Telegram Link 2025

- Web Max Hdcom

- Remoteiot Vpc Network Raspberry Pi Free

How CNC Machining Works: The Core Process

Understanding the practical application of **CNC meaning** involves delving into how these machines actually operate. At its heart, CNC machining is a subtractive manufacturing process. This means it starts with a block of material and removes portions of it to create the desired shape, much like a sculptor carves away stone. The magic lies in the computerized controls and machine tools working in tandem to create custom parts from various materials. This precise removal of material, guided by digital instructions, is what sets CNC apart.

Subtractive Manufacturing at Its Heart

Unlike additive manufacturing (like 3D printing, which builds up material layer by layer), CNC machining precisely cuts, carves, or engraves materials by removing chips or portions. This method is highly effective for achieving tight tolerances and smooth finishes, making it ideal for parts that require structural integrity and exact dimensions. The machine tools, guided by the computer program, perform the physical removal of material, ensuring that the final product matches the digital design with incredible accuracy. This fundamental approach allows for the creation of robust and highly functional components.

The Stages of CNC Machining

The journey from a concept to a finished part via CNC machining typically involves several distinct stages:

- **Design (CAD):** The process begins with a CAD (Computer-Aided Design) model, which is a digital blueprint of the part. Engineers and designers create a 2D or 3D model of the desired component using specialized software.

- **Programming (CAM):** This design is then translated into CAM (Computer-Aided Manufacturing) software. The CAM software generates the G-code – the specific numerical instructions that the CNC machine understands. This code dictates every minute detail: tool paths, feed rates (how fast the tool moves), spindle speeds (how fast the tool rotates), and even coolant flow.

- **Setup:** The raw material is secured in the CNC machine's workholding device, and the appropriate cutting tools are loaded into the machine's tool changer.

- **Execution:** Once the G-code is loaded into the CNC controller, the machine executes these instructions autonomously. The machine tools move precisely along the programmed paths, removing material from the workpiece.

- **Monitoring and Quality Control:** Throughout the process, operators monitor the machine's performance. After machining, the finished part undergoes rigorous quality checks to ensure it meets all specified dimensions and tolerances.

This automated sequence ensures consistency and efficiency across production runs, making CNC machining an indispensable process for modern manufacturing.

Types of CNC Machines and Their Applications

The versatility of **CNC meaning** is best illustrated by the sheer variety of machines that fall under its umbrella. There are countless different types of CNC machines today, each designed for specific tasks and materials. These machines are essentially machine tools that cut or move material as programmed on the controller, as described above. Their applications span across virtually every manufacturing sector, from small workshops to large industrial complexes.

Common CNC Machine Types

The landscape of CNC machinery is diverse, with each type optimized for particular operations:

- **CNC Mills:** These are perhaps the most common type, using rotating cutting tools to remove material from a workpiece that is typically stationary. They can perform operations like drilling, boring, and carving complex 3D shapes, making them incredibly versatile for creating intricate parts.

- **CNC Lathes:** Also known as turning centers, lathes rotate the workpiece while a stationary cutting tool removes material. They are ideal for creating cylindrical parts like shafts, bolts, and discs, often found in automotive and aerospace applications.

- **CNC Routers:** These are semi-manual types of CNC cutters, often used for larger workpieces, especially in woodworking, sign making, and plastic fabrication. They come with a range of tools and primarily rely on a rotating cutting tool to shape and engrave.

- **CNC Plasma Cutters:** These utilize a high-velocity

- Anna Anon

- Viralkand Desi

- Xxl Xxl Xl Pro 2024

- Securely Connect Remote Iot Vpc Raspberry Pi Download Free

- Web Max Hdcom

![What is CNC and CNC Machines? [Easy Introduction]](https://www.cnccookbook.com/wp-content/uploads/2017/08/WhatIsCNCMachining.jpg)

What is CNC and CNC Machines? [Easy Introduction]

What is CNC? - Definition, Functions, And Uses - CTR

What is CNC Machining? | Definition, Processes, Types & Components